ISO 9001 CERTIFICATION

QUALITY MANAGEMENT SYSTEMS (QMS)

OUR SERVICES

.png)

WE UNDERTAKE EVERY STAGE OF THE PROJECT

TO FIT YOUR REQUIREMENTS

Technical Scoping Study

Our process begins with a comprehensive technical scoping study, where we assess the specific needs, constraints, and objectives of your industrial operation. We work closely with your team to understand processes, machinery, and performance goals. This phase ensures that our automation solution is technically sound, cost-effective, and tailored to your industry. The result is a clear, structured plan that guides the electrical, mechanincal and execution phases that follow.

Electrical

Design

Based on the scoping study, we develop detailed electrical designs tailored to your automation needs. We ensure full compliance with industry standards and integrate flexibility for future expansion. Our designs prioritize reliability, energy efficiency, and smooth integration with existing systems—delivering robust electrical infrastructure for demanding industrial environments across divere sectors.

Mechanical

Design

Our mechanical design team transforms process requirements into practical engineering solutions. We create precise mechanical layouts for automated systems, including custom machine components, support structures, and integration interfaces. Every design is optimized for durability, maintainability, and seamless integration into your production line. Whether you’re working with heavy metal processing or delicate packaging operations, we ensure the mechanical framework enhances automation efficiency and supports long-term operational success.

Programming

We develop customized software for Robotic systems. PLCs, HMIs, drives, and other automation components, translating functional specifications into reliable and responsive logic. Our programming ensures smooth communication between systems, intuitive operator interfaces, and real- time process control. With deep expertise across platforms and protocols, we deliver robust code that adapts to the specific needs of each industry and production environment, ensuring optimal performance and uptime.

Manufacturing

We manufacture and assemble electrical panels, electrical cabinets, terminal boxes, sub-cabinets, control boxes and custom mechanical parts according to approved designs. All components undergo thorough quality control and testing to ensure compliance and reliability. Our in-house capabilities allow us to maintain high standards and tight timelines, while ensuring every product integrates seamlessly into the broader automation system.

Installation & Commissioning

Our experienced field team handles the full on-site installation, wiring, and integration of systems. During commissioning, we rigorously test all functionalities, fine-tune system parameters, and ensure optimal performance under real production conditions. Safety, efficiency, and minimal disruption to your operation are our top priorities during this critical phase.

Training

We provide tailored training sessions for operators, technicians, and maintenance staff to ensure safe and effective system use. Our training covers both hardware and software operation, troubleshooting procedures, and best practices. The goal is to empower your team with the knowledge and confidence to operate the automation system independently and efficiently.

Support

Our commitment doesn't end at commissioning. We offer ongoing technical support, remote or on-site diagnostics, and maintenance services. Whether you need urgent troubleshooting or long-term optimization, we’re here to ensure your automation solution continues to deliver value and reliability for years to come.

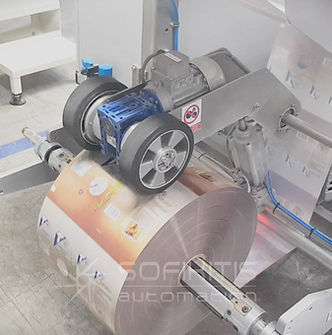

VFFS LINE

The Vertical, Fill, Form and Seal line includes all relative systems for the handling of the product, such as big bag unloading station, shieves, magnet metal separation, packaging machine, check weighter and metal detector. The packaging machine is an intermedent motion VFFS machine. It can handle bulk products with a wide range of granularity. The machine is able to produce diverse types of packages such as pillow bag, block bottom bags, gausset bags, 4 corner sealing, punch-hole bags. It can reach up to 60 products per minute. Special characteristics include automatic volumetric control of the rotary feeding system and automatic film change.

OUR OFF-the-SELF SOLUTIONS INCLUDING EXPERT GUIDANCE & SUPPORT

TOP LOADING PACKER

Fully servo-controlled system that achieves fast and easy format changes that do not require mechanical intervention.

The system can reach high performance reaching 60 packs per minute.

It is specially suited for pharmaceuticals and food & beverage. Depending on the requirements, paper tray can be pre-formed or glued with hot melt adhesive.

SIDE LOADING PACKER

This packer system is fully controlled by servo, allowing for minimal format change times. It is best suited to the needs of food & beverage, as well as paper, plastic and aluminium products.

Options include diverse sub-systems such as one-by-one feeding or flow pockets for asynchronous feeding.

The automation ensures high performance and speed that reaches 80 packs per minute. The in-feed rate can reach 180 products per minute in the case of asychronous loading.

%20(1).png)